|

Products by Casting material Products by final application Products by Casting process +Sand Casting +Investment Casting +Resin Sand Casting +Coated Sand Casting +Die Casting +Pattern Service +CNC Machining |

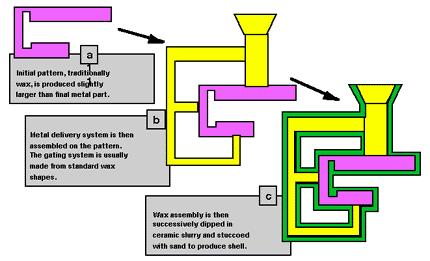

Investment Casting/lost Wax CastingInvestment casting is also known as the lost wax process. Investment casting process is one of the oldest manufacturing processes.Benefits of Investment casting: 1.Intricate shapes can be made with high accuracy. 2. metals that are hard to machine or fabricate are good candidates for this process. 3. It can be used to make parts that cannot be produced by normal manufacturing techniques, such as turbine blades that have complex shapes, or airplane parts that have to withstand high temperatures. The types of materials that can be cast are Aluminum alloys, Bronzes, tool steels, stainless steels, Stellite, Hastelloys, and precious metals. Parts made with investment castings often do not require any further machining, because of the close tolerances that can be achieved. Investment casting, often called lost wax casting, is regarded as a precision casting process to fabricate near-net-shaped metal parts from almost any alloy. Although its history lies to a great extent in the production of art, the most common use of investment casting in more recent history has been the production of components requiring complex, often thin-wall castings. While a complete description of the process is beyond the scope of the discussion here, the sequential steps of the investment casting process will be briefly described, with emphasis on casting from rapid prototyping patterns. The investment casting process begins with fabrication of a sacrificial pattern with the same basic geometrical shape as the finished cast part (Fig. 10.1a). Patterns are normally made of investment casting wax that is injected into a metal wax injection die. Fabricating the injection die often costs tens of thousands of dollars and can require several months of lead time. Once a wax pattern is produced, it is assembled with other wax components to form a metal delivery system (Fig. 10.1b), called the gate and runner system. The entire wax assembly is then dipped in a ceramic slurry, covered with a sand stucco (Fig. 10.1c), and allowed to dry. The dipping and stuccoing process is repeated until a shell of ~6-8 mm (1/4-3/8 in) is applied.  Fig. 10.1. Investment casting process description. Once the ceramic has dried, the entire assembly is placed in a steam autoclave to remove most of the wax (Fig. 10.2a). After autoclaving, the remaining amount of wax that soaked into the ceramic shell is burned out in a furnace (Fig. 10.2b). At this point, all of the residual pattern and gating material is removed, and the ceramic mold remains. The mold is then preheated to a specific temperature and filled with molten metal, creating the metal casting (Fig. 10.3a). Once the casting has cooled sufficiently, the mold shell is chipped away from the casting. Next, the gates and runners are cut from the casting, and final postprocessing (sandblasting, machining) is done to finish the casting (10.3b).  Fig. 10.2. Investment casting process description (cont'd.)  Fig. 10.3. Investment casting process description (cont'd.)

|